Sustainability Series

Sustainable Product Design – Seat Refurbishment

Did you know that construction, demolition, and excavation activities generate approximately 60% of the UK’s waste(1)? With this figure in mind, if you have the option to refurbish your seating, rather than replace then it should be given serious consideration. A new fabric/finish can often have the same impact to the space as completely replacing the seating and refurbishing your seating rather than replacing can help to lower your venues environmental impact!

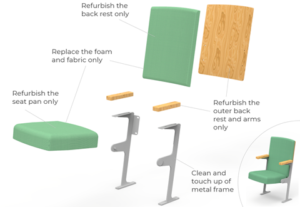

To do this, a survey of your existing seating should be completed by your supplier to determine which parts can be reused in the refurbishment. Often the framework of the seating is still fit for purpose, whereas the upholstery and wood finishes are more susceptible to wear and tear and will be the areas needing attention.

As previously mentioned in our Sustainability series, if the end-of-life is considered at the start of design; products will be designed for disassembly to aid separation to either be disposed of responsibly or remanufactured.

Related Blogs: Sustainable Product Design – Utilising Design Software

How can the seating be disassembled?

Designing a product that can be disassembled links back to the possibility of future refurbishment. It takes into consideration the entire product lifecycle and can be beneficial for cost, transportation, and the environment.

In practice:

- Reduced/No adhesives

- Ask your seating manufacturer about their upholstery methods, some adhesives may be necessary to hold the foam in place, however there are ways to reduce or alleviate adhesives in the upholstery process.

- Opt for non-adhesive fixings when choosing the signage, options such as woodscrews and magnets are preferable over glues or tape, this reduces the use of single use products in the short term and allows the signage to be replaced independently of other areas of the furniture.

- Maintenance

- Seating that can be disassembled allows for the furniture to be maintained more easily – this may be a refurbishment further down the line or day-to-day internal maintenance. Taking care of the seating and replacing only the worn parts will mean that you can extend the furniture’s lifespan and prevent it from going to waste for longer.

- Request a spares package to be supplied as part of the seating order. Having spare parts for the seating when ordering furniture not only enables quicker and easier maintenance, but also means that the materials, processes, and transportation is included in the main order and therefore has a lower environmental impact

- If a self-tipping seat is required explore the mechanism options with your seating manufacturer to ensure that the mechanism is serviceable and/or has a long-life span as moving parts will wear out quicker than the rest of the seating.

- Delivery

- A product that can be easily disassembled allows the packaging to be more compact and can thereby reduce the environmental impact of delivery by reducing the number of journeys required.

Related Blog: Sustainable Product Design – Design for Longevity

In summary, more venues are choosing to refurbish their seating because of the increased focus on net zero carbon and other sustainability aspirations. In doing so they stand to gain from a unique product offering, embodied carbon savings, positive social value impact and more, as well as saving themselves time and money in the process.

Head to our Refurbishment Services to out more about refurbishing your venue and how Race can help.

This article was written originally for the Theatre Greenbook by our Design and Projects Engineer, Kitty Frost, and Sustainability & Environmental Manager, Sian Berkley.

Discover more about Race Furniture’s Sustainability initiatives here

[1]UK Government (2020), UK Statistics on Waste